The Critical Role of High-Definition Imaging

Getting a clear picture underwater is a big deal. Without good visuals, spotting problems on subsea equipment or understanding what’s happening on the seabed is tough. This is where high-definition imaging comes in. It gives operators a much better view, making it easier to see small details that could indicate a problem. A good ROV camera underwater is like the eyes of the operator on the surface. It needs to provide sharp, clear images, even when things are murky or dark. This level of detail is what separates a quick check from a thorough inspection.

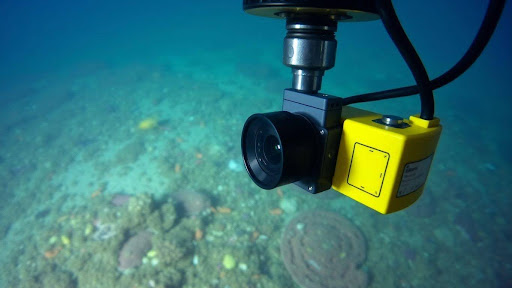

Capturing Detail in Challenging Environments

Underwater conditions are rarely ideal. Sediment, low light, and distance can all make seeing difficult. Advanced ROV camera systems are built to handle this. They use special lighting and high-sensitivity sensors to cut through the gloom. This means that even in deep water or areas with poor visibility, the subsea camera can still pick up the necessary details. Whether it’s checking a pipeline for corrosion or examining a ship’s hull, the ability to capture fine details is key. This is why choosing the right camera for ROV operations is so important.

Real-Time Visual Data for Informed Decisions

What makes ROV operations so effective is the live feed. Operators aren’t guessing; they’re seeing what the ROV sees, right now. This real-time visual data allows for immediate decision-making. If the ROV camera spots an issue, the operator can react instantly, perhaps adjusting the ROV’s position or directing it to get a closer look. This immediate feedback loop is vital for efficiency and safety. The quality of the images from the camera for ROV directly impacts how quickly and accurately decisions can be made, preventing minor issues from becoming major ones.

Improving Operational Efficiency Through ROV Imaging

Reducing Inspection Time and Costs

When you need to check on underwater equipment, especially in places like oil rigs or power plant intakes, sending people down there takes ages and costs a fortune. ROVs, with their high-definition cameras, change that. They can get into tight spots and send back clear pictures and video in real-time. This means you can spot problems like corrosion or blockages much faster than with older methods. This speed directly translates to lower costs because you’re not paying for as much crew time or renting expensive support vessels for as long. The ability to get detailed visual data quickly helps teams plan maintenance more effectively, avoiding costly emergency repairs down the line. It’s all about getting the information you need without the usual hassle.

Minimizing Downtime with Swift Assessments

Nobody likes it when operations have to stop because of an inspection. With ROVs, those stops can be way shorter. Imagine a pipeline that needs a look-over. Instead of shutting down the whole system and bringing in divers, an ROV can be sent out. It can quickly assess the situation, maybe even perform minor tasks, and send back all the visual data needed. This rapid assessment means the system can get back online sooner. This is a big deal for industries where every hour of downtime means lost money. The real-time visual data from the ROV is key here; it lets operators make quick decisions without waiting for someone to surface and report.

Streamlining Maintenance and Repair Planning

Having good visual information from ROV inspections makes planning repairs a lot easier. Instead of guessing what’s wrong, you have clear video and images showing the exact issue. This helps maintenance crews prepare the right tools and parts before they even go to the site. It also helps in prioritizing what needs fixing first. For example, if an ROV spots a small crack in a structure, that can be logged and scheduled for repair before it becomes a major problem. This proactive approach, driven by detailed ROV imaging, saves money and prevents bigger headaches later on. It’s about using the visual evidence to make smarter, more efficient maintenance plans.

Ensuring Safety and Precision in Hazardous Environments

Eliminating Diver Risk with Remote Operations

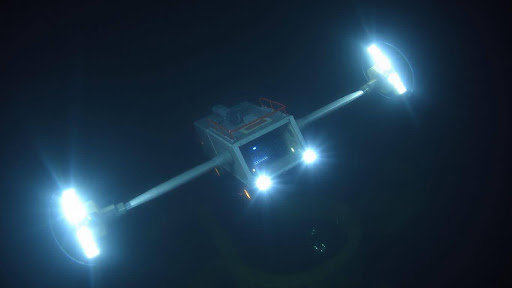

Working underwater, especially in hazardous conditions, used to mean putting human lives on the line. Divers faced risks from pressure, cold, and unseen dangers. Remotely Operated Vehicles (ROVs) change this picture entirely. These machines go where humans can’t, or shouldn’t, safely go. This remote capability drastically cuts down on the risks associated with subsea work. By using ROVs, companies can perform inspections and maintenance without exposing personnel to danger. This shift is a major win for safety protocols in many industries.

Navigating Confined Spaces with Clarity

Many underwater structures, like intake pipes or ship hulls, have tight, complex areas. Getting a human diver into these spots is difficult and dangerous. ROVs, however, are built for this. Their compact design and advanced maneuverability let them get into these tight spots. High-definition cameras on the ROV provide clear views, letting operators see exactly what’s going on. This clarity is key for spotting small issues before they become big problems. The ability to see clearly in confined spaces is a game-changer for maintenance and inspection.

Providing Accurate Visuals for Complex Tasks

When you’re dealing with intricate tasks, like repairing a pipeline or checking the integrity of a dam, you need to see exactly what you’re doing. ROVs equipped with high-resolution cameras and powerful lighting systems give operators a detailed view of the work area. This allows for precise actions, whether it’s guiding a manipulator arm or identifying a specific point of damage. The accurate visual data from ROVs means that complex jobs can be done with greater confidence and accuracy, reducing the chance of errors. This precision is vital for the long-term health of subsea assets.

Applications of High-Resolution ROV Cameras Across Industries

Oil and Gas Infrastructure Integrity

High-definition imaging from ROVs is absolutely vital for keeping oil and gas infrastructure safe and sound. Think about pipelines stretching across the seabed; these are the main arteries for energy. ROVs with their sharp cameras can spot tiny cracks, signs of corrosion, or leaks that might otherwise go unnoticed. This early detection means problems can be fixed before they become massive, expensive failures. It’s all about proactive maintenance, and high-resolution ROV cameras make it possible.

These underwater robots are used for regular checks, ensuring everything is as it should be. They can get up close to structures, providing clear visuals of welds, supports, and the general condition of equipment. This detailed visual data helps engineers plan maintenance schedules more effectively, reducing the need for guesswork and minimizing costly shutdowns. The ability to see clearly in challenging subsea conditions is what makes ROVs so valuable here.

The data captured by these advanced cameras is not just for immediate fixes; it builds a historical record. This record is key for long-term asset management and for meeting strict industry regulations. Without the sharp, detailed images provided by modern ROVs, managing these complex underwater assets would be far riskier and less efficient. High-definition imaging is a game-changer for the oil and gas sector.

Offshore Wind Farm Maintenance

As offshore wind farms grow, so does the need for reliable inspection and maintenance. ROVs play a big part in this. They are used to inspect the foundations of wind turbines, checking for any signs of wear or damage on the structures that sit below the water. They also examine the subsea cables that connect the turbines, looking for any issues that could disrupt power generation.

Using high-resolution ROV cameras, technicians can get a clear view of marine growth on turbine bases and assess the condition of protective coatings. This visual inspection helps in planning cleaning or repair operations, making sure the turbines operate at peak efficiency. It’s a much safer and more cost-effective way to maintain these large, remote structures compared to sending divers.

Here’s a quick look at what ROVs do for wind farms:

- Inspect turbine foundations for structural integrity.

- Examine subsea power cables for damage or wear.

- Monitor the seabed around structures for any changes.

- Assist in the installation of new components.

This consistent monitoring, powered by clear visual data, helps keep renewable energy flowing smoothly.

Marine Research and Ecosystem Monitoring

Marine scientists are increasingly turning to ROVs to explore and understand our oceans. These robots can go to depths that are simply too dangerous or impossible for human divers, opening up new frontiers for research. Equipped with high-definition cameras, ROVs capture stunning footage of marine life and underwater habitats, allowing researchers to study ecosystems without disturbing them.

High-resolution ROV cameras are perfect for observing delicate coral reefs, documenting fish populations, and identifying invasive species. The detailed images and video collected provide invaluable data for scientific studies, helping us understand the health of our oceans and the impact of environmental changes. This visual evidence is crucial for conservation efforts and for tracking biodiversity.

ROVs also assist in collecting samples, such as water or sediment, and can be fitted with various sensors to measure environmental conditions. This multi-faceted approach, combining visual observation with data collection, gives researchers a more complete picture of the underwater world. It’s a powerful tool for expanding our knowledge of marine science.

Search and Recovery Missions

In search and recovery operations, time and accuracy are critical. ROVs equipped with advanced imaging systems are proving to be indispensable tools. They can systematically scan large areas of the seabed, providing clear visual confirmation of objects or debris. This capability significantly speeds up the search process and reduces the risks associated with human divers operating in potentially hazardous conditions.

When a vessel or aircraft goes down, ROVs can be deployed quickly to locate wreckage, assess its stability, and even assist in the recovery of valuable or sensitive items. The high-resolution ROV cameras can capture detailed images of the site, helping investigators understand what happened. Sonar integration also aids in locating targets in murky water where visibility is poor.

Here’s how ROVs improve search and recovery:

- Rapid deployment to search sites.

- Systematic area scanning with precise visual confirmation.

- Reduced risk to human divers.

- Detailed documentation for investigation and recovery.

This technology allows for more efficient and safer operations when every moment counts.

The Technological Advancements in ROV Imaging

Beyond Basic Visuals: Sensors and Sonar Integration

Modern ROV camera systems are doing more than just showing us what’s down there. They’re integrating a whole suite of sensors. Think about it: a high-definition camera captures the visual, but what about things you can’t see? We’re talking about temperature sensors, pressure gauges, and even chemical sniffers. This layered data gives a much fuller picture of the subsea environment. It’s not just about seeing a crack; it’s about seeing the crack and knowing the water pressure and temperature right next to it. This kind of data is gold for detailed inspections.

Sonar is another big player here. In murky water, visual cameras can struggle. That’s where sonar comes in, acting like an underwater radar. It maps out the surroundings, showing shapes and distances even when visibility is zero. Combining sonar with the visual feed from an ROV camera means operators get a complete environmental awareness. This dual approach is key for safe and effective operations in challenging conditions.

- Multi-sensor Fusion: Combining visual, acoustic, and environmental data.

- Advanced Sonar: High-resolution imaging for mapping and object detection.

- Real-time Data Streams: Instantaneous feedback for immediate decision-making.

The integration of multiple data streams transforms a simple camera feed into a rich environmental profile, allowing for more informed actions.

The Impact of 4K and Beyond

Remember when HD was the big deal? Now, we’re talking 4K and even higher resolutions for ROV camera setups. This isn’t just about pretty pictures; it’s about detail. Imagine inspecting a pipeline. With 4K, you can spot tiny bits of corrosion or a hairline crack that you might miss with lower resolution. This level of detail means fewer repeat inspections and more accurate assessments. It’s a game-changer for asset integrity management.

Higher resolutions mean operators can zoom in on specific areas without losing clarity. This is super useful when you’re trying to identify a small anomaly or read a faded label on equipment. It reduces the need to physically move the ROV closer, saving time and reducing the risk of bumping into things. The clarity provided by these advanced ROV camera systems is unmatched.

- Unprecedented Detail: Spotting minute defects and anomalies.

- Enhanced Zoom Capabilities: Close inspection without physical proximity.

- Improved Data Quality: Sharper images for better analysis and reporting.

Lighting Solutions for Deep-Sea Exploration

It gets dark down there. Really dark. So, advanced lighting is a must for any serious ROV camera operation. We’re not just talking about a single spotlight anymore. Modern ROVs use sophisticated LED lighting systems. These can be adjusted in intensity and even color temperature to get the best possible view of the subject. Good lighting can make the difference between seeing a problem and missing it entirely.

These lighting systems are designed to minimize backscatter – that annoying glare you get when light bounces off particles in the water. By using specialized diffusers and strategic placement, the light illuminates the target effectively without overwhelming the camera. This allows the ROV camera to capture clear, detailed images even in the murkiest depths. Effective lighting is as important as the camera itself for subsea visibility.

- Adjustable LED Arrays: Tailoring light output to conditions.

- Backscatter Reduction: Minimizing glare for clearer images.

- Color Temperature Control: Optimizing visual representation of subsea objects.

Data Integrity and Compliance with ROV Footage

Creating Comprehensive Inspection Reports

High-definition imaging from ROVs is a game-changer for creating detailed inspection reports. The clarity of 4K footage means operators can zoom in on small details, like hairline cracks or minor corrosion, that might be missed with lower-resolution cameras. This level of detail is vital for accurate record-keeping. The ability to capture and store this visual data ensures that every aspect of an inspection is documented thoroughly. This makes it easier to track changes over time and identify trends that could indicate potential problems down the line. The data integrity of these reports is paramount for operational awareness.

Satisfying Regulatory Requirements

Many industries have strict regulations regarding infrastructure inspection and maintenance. ROV footage provides objective, verifiable evidence that these requirements are being met. Regulatory bodies often require detailed visual documentation, and the high-resolution output from modern ROV cameras easily satisfies these demands. This visual proof helps companies avoid penalties and maintain their operating licenses. It’s not just about seeing; it’s about having proof that the job was done right, according to the rules. This is where the data integrity of ROV footage really shines.

Archiving Visual Evidence for Future Reference

Beyond immediate reporting and compliance, archiving ROV footage offers significant long-term benefits. This visual record serves as a historical baseline for assets. When future inspections occur, operators can compare current footage with past recordings to assess the rate of degradation or the effectiveness of repairs. This historical data is invaluable for predictive maintenance, allowing for proactive interventions rather than reactive fixes. It also aids in training new personnel, providing real-world examples of various conditions and issues encountered subsea. The archived visual evidence is a powerful tool for continuous improvement and risk management.

Looking Ahead

So, it’s pretty clear that high-definition imaging on ROVs isn’t just a nice-to-have anymore. It’s really become a standard part of the job for anyone working underwater. Whether you’re checking pipelines, looking at wind turbine foundations, or exploring the ocean floor, seeing things clearly makes a huge difference. It means fewer mistakes, better data, and ultimately, safer and more efficient work. As the technology keeps getting better, we can expect ROVs to do even more, but that sharp, clear view will always be the foundation for success.