Understanding Production Efficiency in Manufacturing

The current manufacturing industry must solve an urgent problem which requires higher output rates and decreased waste generation and fewer production stoppages. Business organizations actively seek operational efficiency improvements to stay competitive in the current fast-paced business environment. The main goal of this initiative focuses on reaching optimization by improving production efficiency. The Production Efficiency Dashboard shows the ability of a manufacturing system to transform raw materials and labor and machine time into finished products. The more efficiently this transformation occurs, the more value a company can generate with the same or fewer resources.

Manufacturers measure their operational performance through production efficiency which they express as a numerical value. The system evaluates multiple elements which include production speed and resource usage and tool operation and workflow performance. A company that produces a high volume of quality products with minimal waste and downtime is considered efficient. A state of optimal performance needs organizations to understand their KPIs and obtain real-time precise data for decision-making.

What Is a Production Efficiency Dashboard?

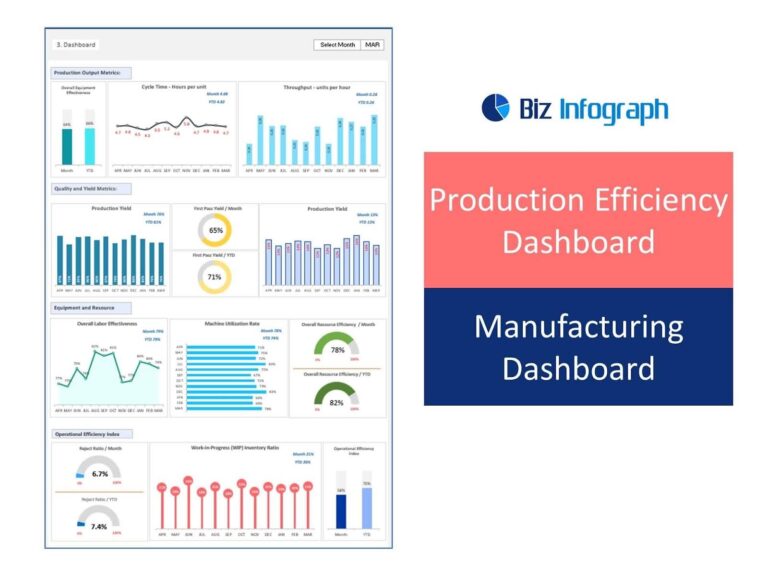

Manufacturing operations with advanced complexity and large volumes of data require manual performance information management to become unfeasible. The need for production efficiency dashboards has become so great that numerous businesses now use them. A production efficiency dashboard serves as a visual management tool which combines vital production data into an easy-to-use interface. The system converts unprocessed production information into useful data which enables managers and operators to detect patterns and irregularities and discover areas for improvement.

A dashboard achieves its value through its function to combine various data sources into one centralized platform. The dashboard collects data from various sources to display information about machine outputs and labor performance and quality checks and maintenance logs in a unified interface. The consolidated view removes the requirement to access different spreadsheets and reports and systems for production health monitoring. Decision-makers can make decisions more quickly and with greater assurance because all information is accessible in a single location.

The main advantage of a dashboard includes its ability to show current data in real time. Instead of relying on end-of-shift or weekly reports, supervisors can see what is happening on the factory floor as it occurs. The system generates alerts through performance metric thresholds which enable operators to take immediate action against emerging problems. Real-time problem detection enables organizations to stop small issues from becoming major production disruptions by identifying them before they grow out of control.

Cycle time and takt time function as fundamental performance measurement tools. The duration needed to finish one production unit runs from beginning to end defines cycle time. The production speed required to fulfill customer needs appears in Takt time. Comparing these two metrics allows manufacturers to align production rates with demand, identify bottlenecks, and adjust workflows accordingly.

The evaluation of machine effectiveness depends on two key factors which are downtime and equipment utilization. Equipment downtime refers to the period when machines cease operation because of equipment failures or maintenance activities or changes in setup configurations. The system becomes unavailable for extended periods which results in decreased production output and requires better maintenance approaches and process optimization. The percentage of available machine operating time that produces productive output defines equipment utilization. The system shows low utilization which could be due to excessive capacity or scheduling problems or operational inefficiencies.

The rates of scrap and rework production reveal details about product quality standards and production process reliability. Scrap materials consist of items which cannot be transformed back into usable form and require disposal. The process of rework demands human workers or machine operating time to correct defective products. The high levels of scrap and rework waste resources while simultaneously leading to decreased customer satisfaction. The dashboard includes these metrics to enable quality teams to detect source problems which they can address through corrective measures.

Implementing and Customizing Your Dashboard

The first step to create an efficient production efficiency dashboard system requires choosing suitable software platforms. The selection of an ideal platform depends on the dimensions of your operation and system complexity and current system infrastructure. Smaller manufacturers tend to create their dashboards through Excel spreadsheets. The tools create an essential performance monitoring system through their display of charts and tables and their ability to produce warning signals based on color codes. The system needs manual updates for its operation, but it does not provide real-time capabilities.

Power BI and Tableau and manufacturing execution system platforms offer business intelligence tools that support complex requirements through their advanced functionalities. The tools provide users with direct access to machines and sensors and ERP systems which enable automatic data collection and system updates. The system enables users to access complete information through its advanced visualization tools and interactive features which let them analyze specific data points and results by time or product or shift.

The process of creating dashboards for user-friendly operation stands as a fundamental requirement. A dashboard needs to have an intuitive design which allows users to understand information quickly through visual inspection. Users can check performance speed through visual indicators that show color signals and trend lines and status indicators. The data needs to follow a logical structure which puts essential metrics in clear positions while keeping additional details reachable. The dashboard loses its effectiveness when it shows too much data which makes users become confused.

The dashboard insights serve as a tool to support ongoing operational enhancement.

A production efficiency dashboard should not be a static report. Its greatest value lies in how it is used to drive continuous improvement. Teams can track their performance and stay accountable through dashboard data review which helps them detect performance obstacles while assessing the effects of implemented changes.

The identification of bottlenecks stands as one of the primary applications of dashboard insights. The production process indicates constraints when it fails to meet its expected output levels and production cycles take longer than usual. Identifying the root cause of inefficiency enables organizations to implement specific solutions for addressing problems such as slow machines and labor shortages and quality issues. Over time, addressing these bottlenecks leads to smoother workflows and more predictable output.

Conclusion

Manufacturers need to achieve their highest production levels because the current manufacturing market demands it for their business survival. Organizations that achieve higher output with reduced resources and fast adaptation and stable quality performance will gain market leadership. A production efficiency dashboard serves as a strong instrument which enables manufacturers to achieve their objective.

The production process achieves complete transparency through dashboards which present vital performance indicators in an easily readable format. The system allows for real-time monitoring and historical analysis and continuous improvement. The implementation of a dashboard system for bottleneck detection and performance measurement leads organizations toward operational excellence. Bizinfograph offers ready-to-use dashboard templates on Finance, Sales, HR and Manufacturing.